New York has one of the strictest cannabis testing regimes in the United States. Every batch of regulated cannabis must pass third-party testing before it can reach dispensary shelves, and pesticide testing sits right at the center of that safety framework.

If you grow, process, or manufacture cannabis products in New York, pesticide testing is not just a lab checkbox. It is a core part of license protection, brand protection, and consumer protection. Failing pesticide tests can mean:

- Mandatory destruction of inventory

- Costly recalls and investigations

- Damage to your reputation with retailers and patients

In this guide, we break down how pesticide testing for cannabis in NY works, what the OCM pesticide limits mean in practice, where operators most often run into trouble, and how to work with a lab like DRS Testing to avoid failures.

What Is Pesticide Testing in NY Cannabis?

Pesticide testing checks cannabis products for residues of:

- Fungicides

- Insecticides

- Plant growth regulators

- Other agricultural chemicals used during cultivation or post-harvest handling

Cannabis is a bioaccumulator. It draws chemicals from soil, water, foliar sprays, and even the air. When you concentrate cannabinoids into extracts and vapes, you may also concentrate any pesticides that are present.

New York’s Office of Cannabis Management (OCM) requires licensed labs to screen cannabis for a defined list of pesticides and compare results to regulatory action levels. If a product:

- Contains a prohibited pesticide, or

- Exceeds the allowed limit for an approved pesticide

Then the batch is adulterated and cannot be sold. In some cases, it must be destroyed rather than remediated.

For operators, pesticide testing is therefore both a safety tool and a compliance gate. If you understand the panel and the limits, you can design your IPM program and sourcing around passing on the first attempt.

How OCM Pesticide Limits and Action Levels Work

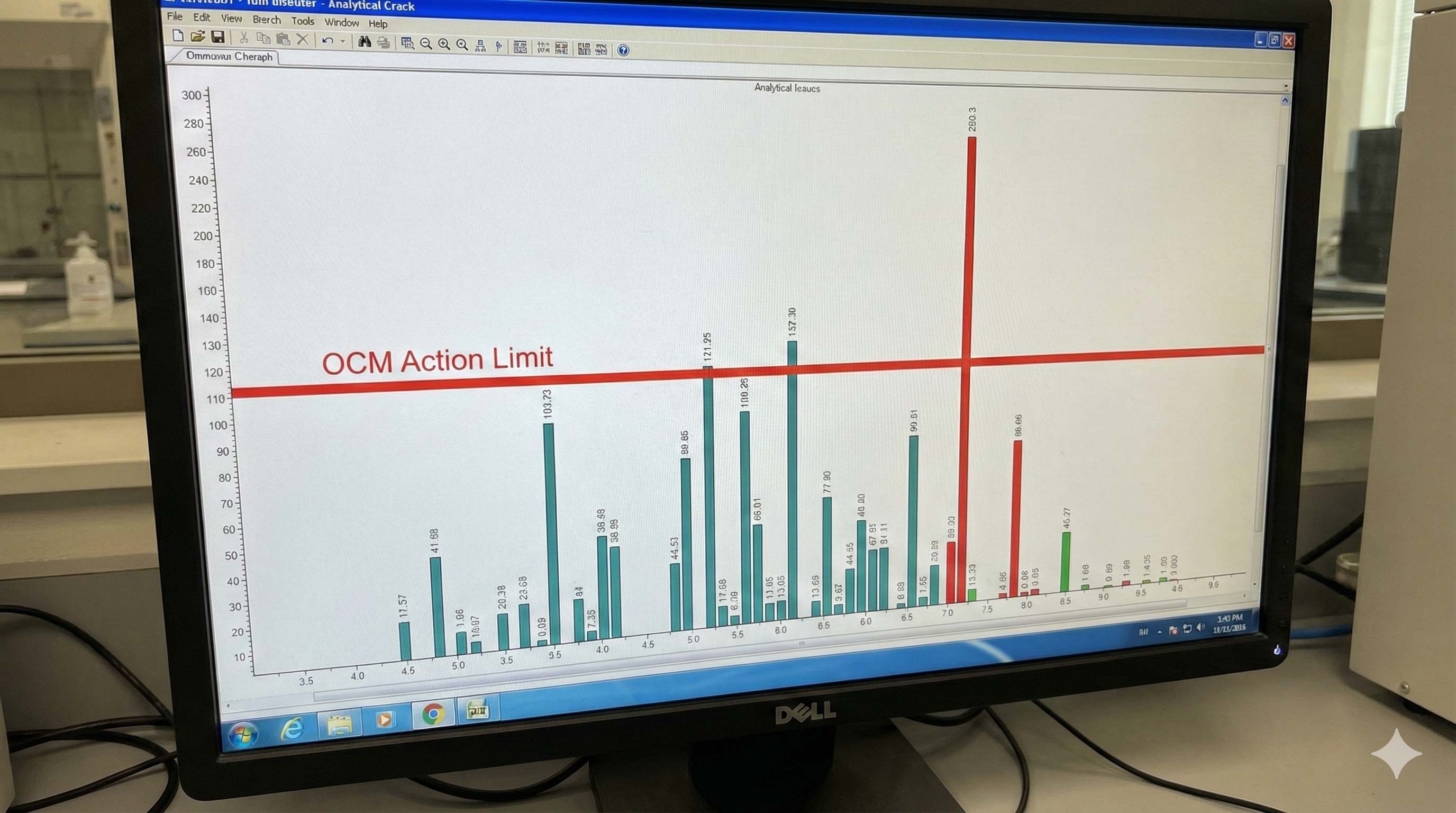

OCM publishes a Laboratory Testing Limits document that sets action levels for each required analyte. An action level is the maximum concentration that can appear in a cannabis product and still be considered acceptable.

Conceptually:

If a pesticide result is at or below the OCM action level, the batch can pass (assuming all other tests pass).

If a result is above the action level or involves a prohibited pesticide, the batch fails pesticide testing.

New York’s limits sit in the low parts per million or even parts per billion range for many pesticides. For example:

- Natural pyrethrins in cannabis are typically limited to roughly the 1 ppm range across many state programs, including New York. Regulators treat higher levels as a serious red flag for improper insecticide use.

- The myclobutanil limit in NY is effectively zero for regulated cannabis. Myclobutanil can degrade to hydrogen cyanide when heated, so any detection in inhalable products will usually trigger an automatic failure.

OCM has already issued public recalls where lab results showed “unallowable levels of pesticides,” and products had to be removed from shelves. That is the practical impact of these action levels.

You can think of OCM pesticide limits as:

- A hard safety boundary

- A compliance threshold that you must design your entire spraying, sourcing, and processing ecosystem around

What Is in a Typical NY Pesticide Panel?

An OCM permitted cannabis lab will build its pesticide panel around the state’s analyte list. At DRS Testing, the panel is designed for New York regulators and New York cultivation practices.

Here is a simplified view of the types of pesticides we commonly screen for:

|

Class |

Examples |

Typical Use |

|

Fungicides |

Myclobutanil, Boscalid, Tebuconazole |

Powdery mildew, mold control |

|

Pyrethroid insecticides |

Permethrins, Cyfluthrin, Cypermethrin |

Broad spectrum insect control |

|

Natural pyrethrins |

Pyrethrins, Piperonyl butoxide |

“Natural” insecticide formulations |

|

Neonicotinoids |

Imidacloprid, Thiamethoxam, Acetamiprid |

Systemic insect control |

|

Organophosphates |

Chlorpyrifos, Diazinon, Naled |

Legacy insecticides, often prohibited |

|

Carbamates |

Carbaryl, Carbofuran, Oxamyl |

Insect control, often tightly restricted |

|

Plant growth regulators |

Paclobutrazol, Chlormequat chloride |

Growth control, often not allowed in cannabis |

New York addresses these substances in two ways:

- Some pesticides are prohibited outright in cannabis. Any detection leads to failure.

- Others have a numeric action level, and you must be at or below that number to pass.

When you receive a pesticide COA in New York, each analyte will show:

- A measured value (for example, 0.12 ppm)

- The associated action level for that analyte

- A pass or fail flag

If you advertise clean or pesticide-free products, this document is your proof.

How Labs Actually Test Pesticides: QuEChERS, LC-MS and GC-MS

Modern cannabis labs do not measure pesticides with simple test strips. The chemistry is far more sophisticated.

Most New York labs follow a workflow built around QuEChERS cannabis extraction and tandem mass spectrometry.

QuEChERS Preparation

QuEChERS stands for Quick, Easy, Cheap, Effective, Rugged, Safe. It is a standardized approach that works very well on complex plant matrices like cannabis.

In simplified terms:

- The lab homogenizes the cannabis flower or product.

- The analyst adds a solvent like acetonitrile and special salts.

- Pesticides move into the solvent layer.

- The lab cleans up the extract with sorbents that remove pigments, oils, and other interferences.

The result is a relatively clean extract that contains a wide range of pesticide analytes in a form that instruments can measure.

LC MS/MS and GC MS/MS

From there, labs use liquid chromatography tandem mass spectrometry (LC-MS/MS) and gas chromatography tandem mass spectrometry (GC-MS/MS).

- LC-MS/MS works well for more polar and thermally sensitive pesticides.

- GC-MS/MS works well for volatile and semi-volatile analytes.

By combining these two platforms, a lab like DRS Testing can:

- Cover dozens of pesticides in one run

- Achieve very low detection limits

- Distinguish target analytes from background noise

This is what allows us to confidently say whether a sample passes or fails OCM pesticide limits.

Key Pesticides to Understand in New York

Some pesticides consistently show up as high risk in adult use and medical cannabis. It pays to know them by name.

Myclobutanil

- Class: Fungicide

- Typical use: Powdery mildew control in traditional agriculture

- New York's status on cannabis: Treated as effectively prohibited

When heated, myclobutanil can break down into hydrogen cyanide gas. Because cannabis is often smoked or vaporized, regulators have very little tolerance for this pesticide.

If a lab detects myclobutanil in your flower, pre-rolls, vapes, or concentrates, you should assume:

- The batch will fail

- Remediation options will be limited

- You will need to investigate your spray history and sourcing

This is why understanding the myclobutanil limit in NY is so important. In practical terms, your limit is “non-detect.”

Pyrethrins and Pyrethroids

Many growers assume that “natural” pyrethrins in cannabis or pyrethroid products are safe because they appear on home and garden labels. New York disagrees when it comes to inhaled cannabis.

- Pyrethrins and piperonyl butoxide usually have very low ppm limits.

- Permethrins and other pyrethroids also carry strict action levels.

If you use pyrethrin-based sprays late in flower or in indoor spaces without proper IPM planning, you risk residues above the allowed limit. That is a recipe for failure, especially if concentrates or vapes amplify the contamination.

Organophosphates and Carbamates

Older insecticides such as:

- Chlorpyrifos

- Diazinon

- Naled

- Carbaryl

- Carbofuran

They are tightly controlled or completely banned in New York cannabis. Any detection can trigger an automatic failure.

These compounds are toxic even at low levels. They also send a bad signal to regulators about controls and sourcing. You should avoid them entirely in your cannabis supply chain.

Common Failure Points in NY Pesticide Testing

From what we see in the lab and in public recall notices, failures usually cluster around a few patterns.

Off-label or legacy pesticide use

Operators sometimes inherit old IPM practices from other crops. They may:

- Use products that are legal for tomatoes but not approved for cannabis

- Follow off-label dilution rates or spray intervals

- Rely on agricultural suppliers who do not understand cannabis regulations

This is a fast way to trip New York’s pesticide testing thresholds. If a product is not clearly allowed for cannabis under New York rules, do not use it.

Late flower or post-harvest spraying

Pesticides applied late in the flowering cycle or after harvest have little time to dissipate or break down. That is especially true in indoor environments with less rainfall and fewer natural degradation factors.

Flowers treated shortly before harvest are much more likely to fail testing. So are post-harvest treatments on hanging plants or dried buds.

Concentration in extracts and vapes

Extraction does not always remove pesticides. In some cases, it concentrates them.

A flower lot that is just under the limit may produce a distillate that is well above the limit. That is why processors need to know:

- The spray history and IPM practices of the farms they buy from

- The pesticide profile of their input material, especially trim and biomass

You cannot afford to turn a marginal flower batch into a failed oil batch.

Poor documentation and traceability

When OCM investigates a pesticide failure, regulators will look at:

- Spray logs

- Supplier documentation

- Batch records

- COAs from previous stages

Missing or inconsistent records make it harder to show that an issue was an isolated mistake. That can increase regulatory risk.

Compliance Best Practices for Growers and Processors

You cannot control every variable in agriculture, but you can significantly reduce your pesticide risk with disciplined systems.

Here are practical steps we encourage clients to follow:

Build a cannabis specific IPM program

- Use only pesticides that are compatible with cannabis and New York rules.

- Favor biological controls and low-risk chemistries.

- Phase out any products that contain high-risk active ingredients such as myclobutanil or organophosphates.

Document your program and review it regularly as guidance evolves.

Test early and screen inputs

- Pre-screen high-risk flower or biomass before large-scale extraction.

- Test a small subset of new suppliers before you rely on them for major volumes.

- Use pesticide testing as a supplier qualification tool, not just an end-of-line check.

Align formulations with realistic limits

If you know New York’s action levels sit in the low ppm range, formulate and blend conservatively.

- Avoid mixing a borderline batch with another borderline batch.

- Do not assume dilution will solve a pesticide problem. Regulators can still detect the source if you blend.

Plan to meet the limit with a comfortable margin.

Work with an OCM-focused lab

Choose a lab that:

- Understands pesticide testing of cannabis in New York from both the chemistry and regulatory sides

- Uses validated QuEChERS cannabis workflows, LC MS/MS, and GC MS/MS

- Presents results clearly against OCM pesticide limits

A strong lab partner will alert you to patterns and help you see issues before OCM does.

Why Work With DRS Testing for Pesticide Compliance

At DRS Testing, we built our pesticide testing service specifically for New York cannabis operators.

When you send us samples, you get:

- A New York-focused pesticide panel that aligns with the OCM analyte list and action levels

- QuEChERS-based extraction and dual platform LC-MS/MS plus GC-MS/MS analysis

- Clear COAs that highlight results relative to OCM pesticide limits and flag anything that is close to an action level

- Access to scientists who can explain results in plain language and help you trace likely sources of contamination

- Turnaround times that support real production schedules rather than delay them

You can learn more about our dedicated service on the pesticide testing page and explore related educational content on the DRS Testing blog.

Final Thoughts and Next Steps

Pesticide testing in New York is not going to get looser over time. If anything, limits will stay tight and enforcement will remain active as the market matures.

For cannabis businesses, that means:

- Treat pesticide control as part of your GMP program

- Invest in clean inputs and sound IPM, not short-term fixes

- Build a relationship with a lab that understands New York regulators

When you design your cultivation, sourcing, and processing decisions around passing pesticide testing on the first try, you protect your inventory, your license, and your brand.

You do the growing.

We will handle the data that keeps your products on shelves.

Leave a Comment